Acrylic can also be directly punched. Compared with glass, acrylic has very good mechanical processing characteristics. The use of laser cutting and punching has very high assembly accuracy. You only need to make pictures in the computer. The computer punched the acrylic.

Acrylic itself has high transparency. Polishing acrylic makes it have crystal-like high transparency. The polished acrylic is very smooth and highly appreciative. It can be used for many kinds of crafts. Acrylic material will melt at 70°-100°, and this heat can be used to modify the shape of acrylic, including irregular shapes.

Acrylic hot bending can be done in different ways. Many acrylic sheets can be placed on a set of hot bending machine and forming mold at the same time for hot bending and shaping. Most hot bending only passes through single or parallel hot bending. The point of view of the hot bending can be fixed according to the needs to control the point of view.

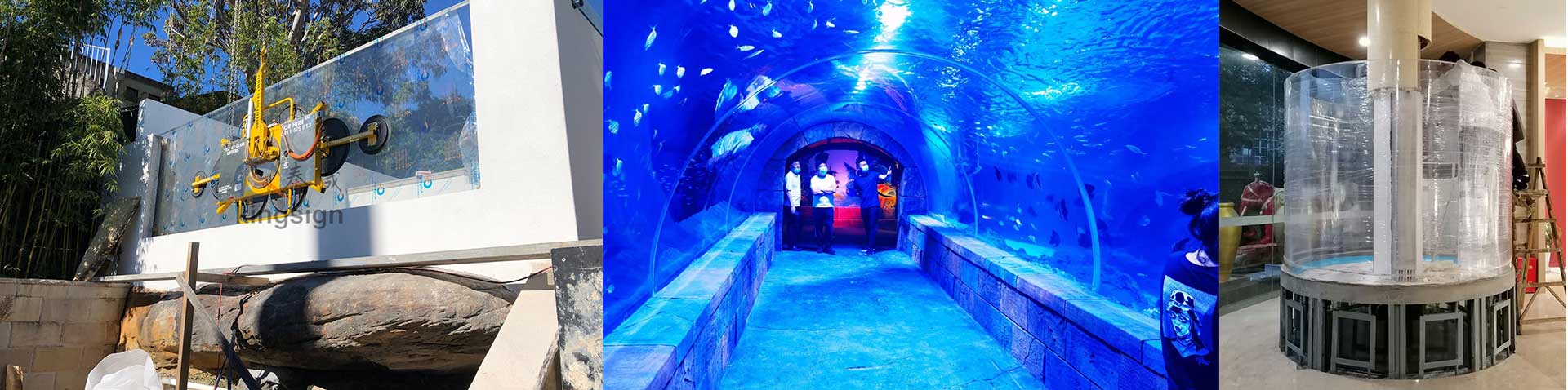

KINGSIGN® ACRYLIC is specialized in all kinds of Acrylic sheet, acrylic window, acrylic tunnel, acrylic marine hall, acrylic aquarium, acrylic swimming pool, acrylic fish tank, acrylic semi-finished processing parts, acrylic bonding acrylic glue, curved acrylic sheet, large-scale acrylic sheet installation service. for details, please consult: 0086 13370079013(Whatsapp/Wechat)