Aquarium Windows

1.Why is Kingsign acrylic aquariums?

Kingsign factory has been working on thick acrylic block sheet for more than 20 years. We have the most advanced production and processing equipment, and we have an engineering and technical team that has studied and trained abroad, and a high-quality sales team that has been professionally trained . Now, we can tell all our clients confidently, Kingsign block acrylic sheets and reprocessed acrylic products is the best quality in China.

■ 30 years against yellowing warranty.

■ Super high Chemical bonding technology, 100% guarantee that there are no bubbles or cracks in the splicing place.

■ We can reprocessing acrylic into any shape by 9000*3400*3500mm size oven. Only you dare to design, we just have the ability to manufacture it out.

■ One-stop service. We provide three modules service: design→acrylic manufacturing ( acrylic sheet/tunnel/dome/particular shape)→installation. We have professional engineer to solve your problems at any time. To choose us, to choose efficient and reliable partner.

■ Quick delivery time, and reply every client within 24 hours, and all year no rest days.

2.Aquarium Windows Specification

|

Quality |

100% virgin of Lucite or Mitsubishi MMA materials |

|||

|

HS code |

39205100 |

Density |

1.2g/cm3 |

|

|

Color |

Clear, transparent |

MOQ |

1pcs |

|

|

Thickness:20-300mm cast block, 300-800mm laminated acrylic |

||||

|

Mold sizes of acrylic panel sizes: |

||||

|

1300x2500mm |

1350x2650mm |

1450x2700mm |

1600x2600mm |

|

|

1650x3150mm |

2200x3200mm |

1650x3500mm |

2750x4250mm |

|

|

1800x5000mm |

2100x5500mm |

3000x6200mm |

3000x6700mm |

|

|

3000x8200mm |

3000x8700mm |

3000x11500mm |

3700x8100mm |

|

|

Any other sizes can custom by chemical bonding and bending |

||||

3.Aquarium Windows Production and Feature

|

|

|

|

|

(1) Refined raw materials |

(2) Cast Acrylic Sheet |

(3) Cutting |

|

|

|

|

|

(6) QC Inspection |

(5) Multiple polishing |

(4) Bond or bend |

|

|

|

|

|

(7) Double film |

(8) Packing |

(9) Shipping |

Kingsign Warranty:

1.100% virgin of Mitsubishi MMA new materials

2.UV resistant and warranty 30 years against yellowing

Kingsign technology:

1.Any shape and size custom production with our big size Automatic oven and Five-axis machining machine.

2.We chemical bonding acrylic sheets in factory into any customized angles, 90°120°180°... or bending the sheets into any shape. You design, we undertake the aquarium windows production according to the design. We guarantee that the raw materials fully integrated, strong enough, no bubbles, no yellowing at the joint place.

Kingsign service:

For very large projects, oversize or big water capacity, kingsign provides finite element analysis evaluation reports to confirm the safety acrylic aquarium windows thickness.We also provide professional drawings for clients before quotation and before placing orders.

4.Delivery and product details

Delivery time: 7-25 days

Packing: Kingsign brand PE film on the double sides of acrylic windows, packed with iron pallets/frames.

Process: aquarium windows one long side surface polish and edge chamfer process.

5.Shipping

Normal size can shipping by 20ft or 40ft containers.

Too big size acrylic pool windows need to ship by OT or FR containers.

6.Installation

Kingsign team provide the installation service or online installation training or installation Guidance Document .

1.Waterproof work

2.Silicone Glazing

3.On site chemical bonding work.

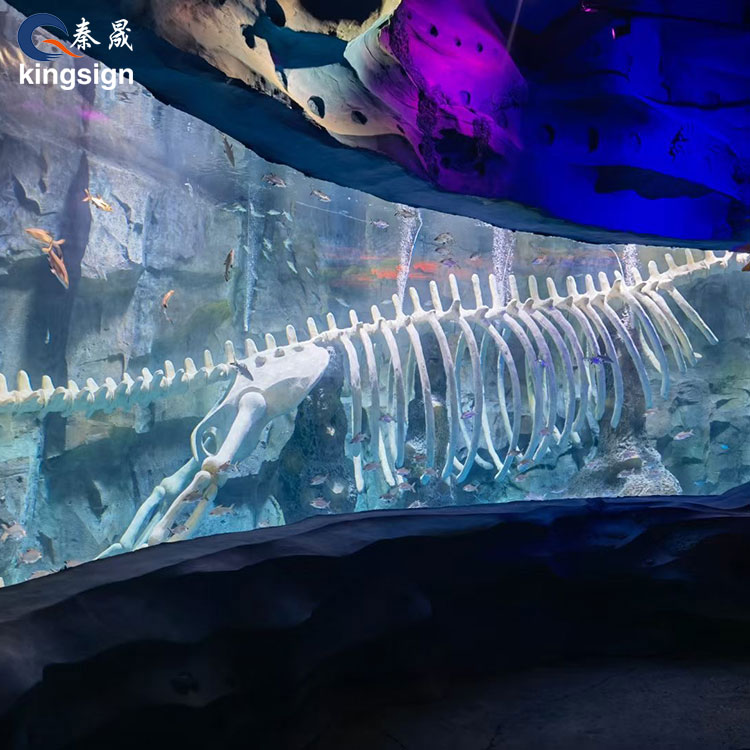

7.Finished Aquarium Windows Photo album

Acrylic panels is easy to processing any shape, light weight, more impact resistant, acrylic aquarium is a popular trend to replace glass aquarium, it is hot to design as acrylic windows for aquarium .

Application occasions: private villas, hotels, resorts, scenic spots, communities